It has been a while since we have posted on this blog, however in that time we have been very busy and the design phase of our project is almost completed.

The gas triggering system has been finalized for the gun. The changes from the first iteration and the final P&ID can be seen by clicking

here. Most of the parts have been ordered and have arrived, therefore Ryan has started laying out and assembling some of the plumbing.

The design of the gun has been finalized and we are in the final stages of finishing the engineering drawings for the gun.

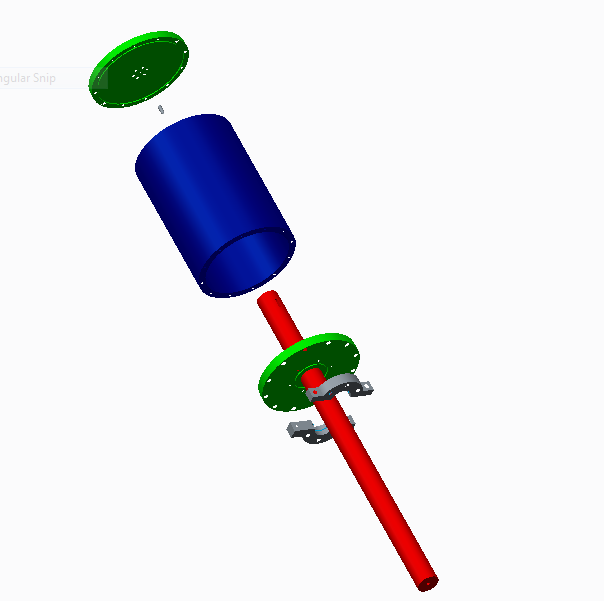

A design change that came about was the design of the front flange . In our initial design, we had two coupling pieces which attached to each other and clamped to the front of the barrel and secured to the front endplate. This design required bolting to occur in two different directions, thus creating shear forces in two directions which would not be ideal. A new design was created that included a collar type piece which would be inserted on the barrel and then bolt to the front endplate from the inside with a unique diagonal o-ring groove mating the barrel and front endplate. With this design, the need for bolting in two different directions is eliminated and it is easier to manufacture. For a better illustration of the new design, please see the most up to date engineering drawings by clicking

here.

Since one of the objectives of this project was to create a gun that would incorporate standardized parts and off the shelf materials, we decided to design the gun per ASTM specifications for the breech and flanges being used. We are using Schedule 20 piping for the breech and Class #150 flanges and endplates.

After designing the gun, we realized the hardest component to acquire would be the barrel. The barrel must be held to extremely precise tolerances so as to reduce friction and ensure optimal firing of the projectile. We first decided to investigate if a rifle barrel would work for our purposes. Rifle barrels are built with high precision and have high standards, and they are somewhat cheaper to obtain as well. When we contacted some vendors, however, the lead times they provided were outside the scope of our timeline. We then started looking into precision deep hole drilling specialists who specialize in drilling precise holes in materials. In this scenario, we would provide them stock material and they would bore out a hole for us. Ultimately, we were able to find a vendor that could not only provide us with a precision deep hole, but would also include the machining of the flange and welding for a reasonable price. We have selected this vendor and are currently working with them to have the order in soon.

The electronic triggering system is also currently being ordered. A preliminary diagram is shown below.

In addition to the basic triggering system, for additional safety, we are designing a digital logic gate circuit to which door sensors and other sensors can be added. This means that all doors must be closed and other sensors must register as clear in order for the gun's firing system to be operational.

Using an AND gate, we can achieve this. An AND gate will output a HIGH signal only when both inputs are HIGH. Therefore, in order for the system to be used, all sensors must be engaged.

The next few weeks will be dedicated to receiving all of our ordered parts and we will be starting to build our setup. We have started laying out our plans for the piping from the compressed air tanks to the gun and have done some initial building. We also need to design a table for our gun to sit on and we are currently looking at using strut channel because of its easy construction and the module nature of strut channel. We'll be posting pictures as the build progresses, so stay tuned.